In-Situ Resource Utilization (ISRU)

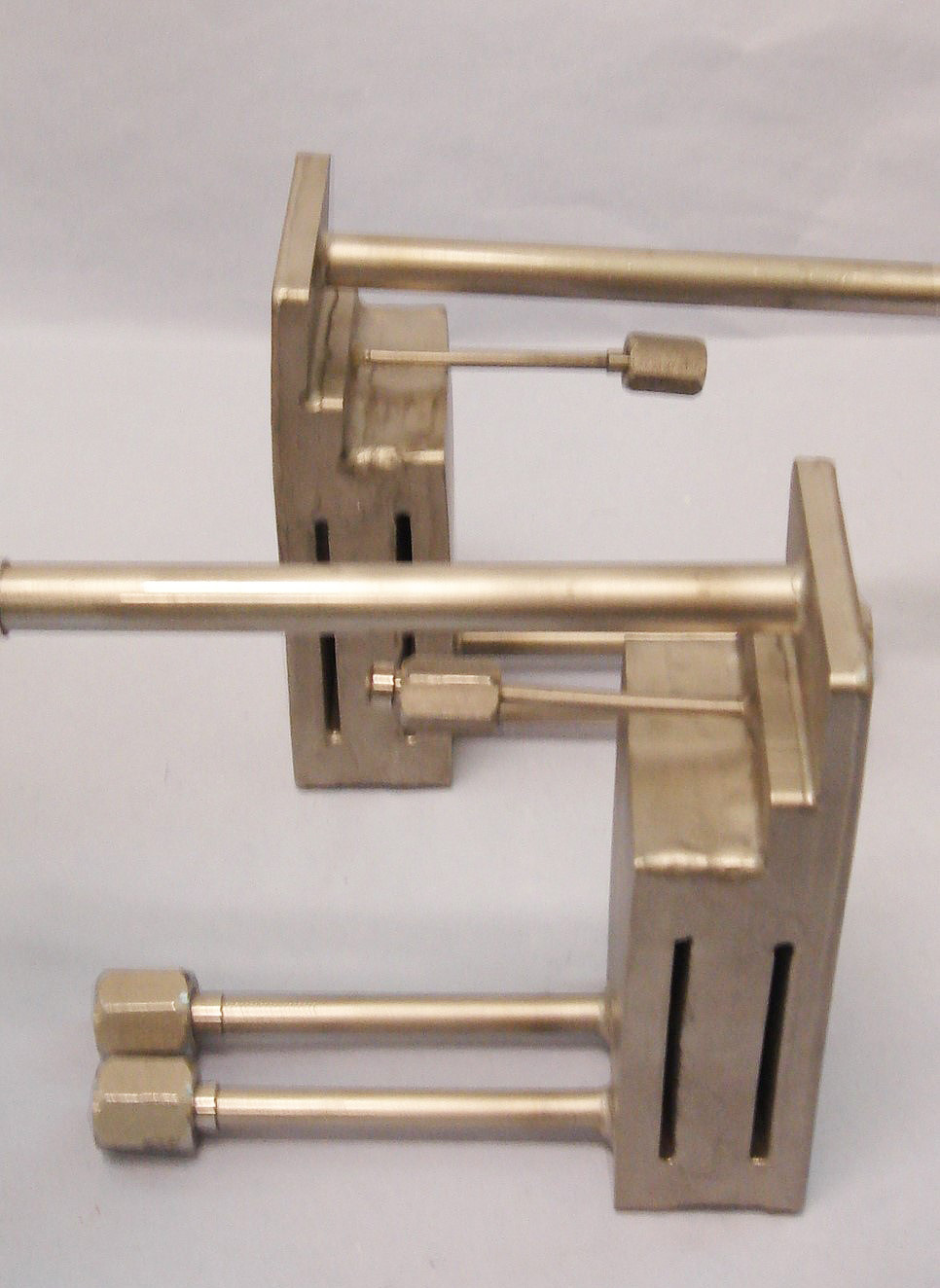

Sustainable execution of prolonged space missions depends upon the utilization of local resources and waste products from manned spacecraft and planetary bases. Successful in-situ resource utilization (ISRU) will require component technologies which are optimal in size, weight, volume and power efficiency.

ISRU gives more flexibility to extravehicular activities by incorporating portable life support systems, improves mobility by providing fuel for rovers and increases mission longevity by producing fuel for return missions.

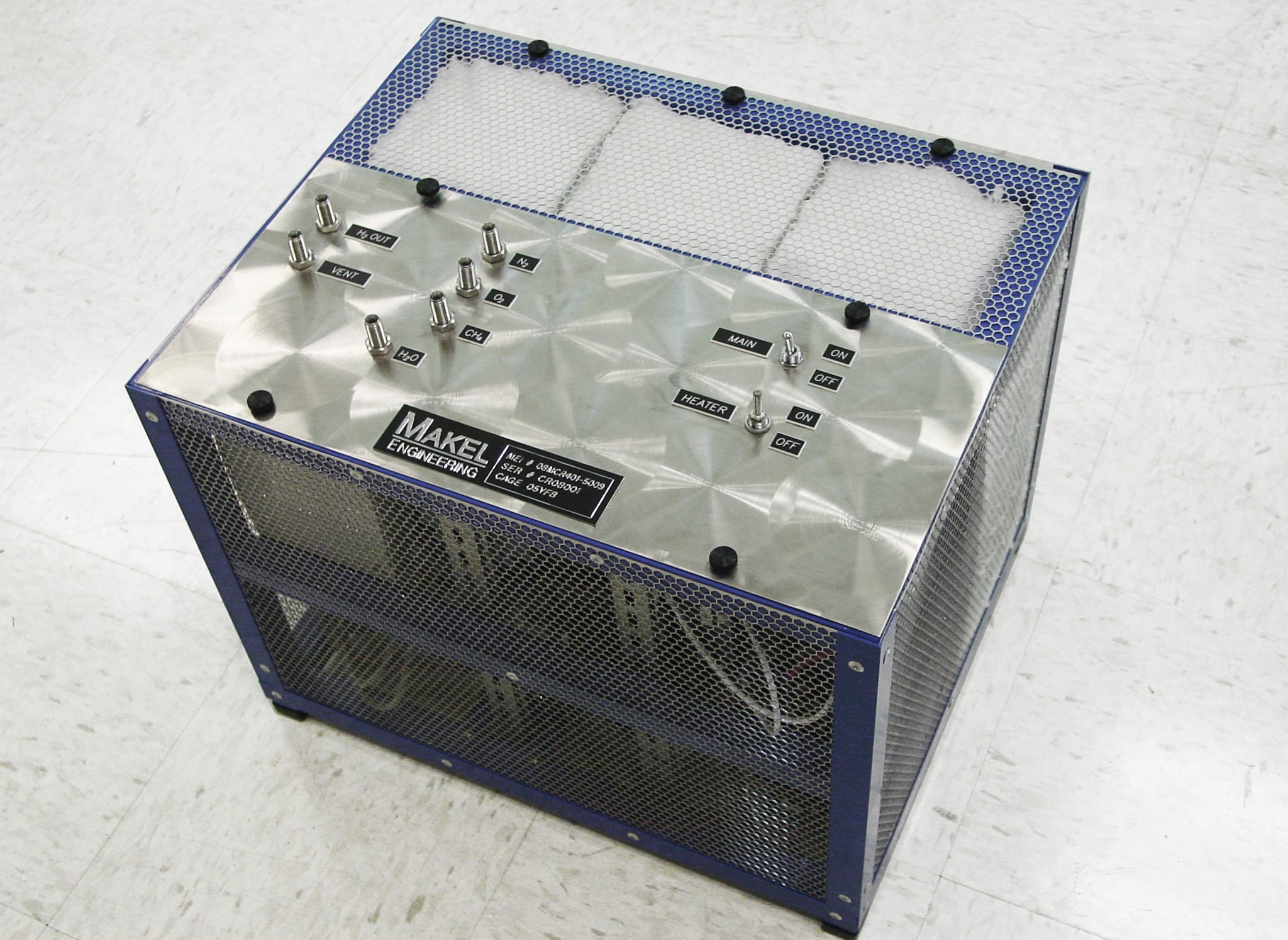

In-Situ Manufacture of Plastics and Composites

Polyethylene can be synthesized from carbon dioxide and water (Mars in-situ resources) and metabolic waste. Once synthesized, polyethylene can be used for the fabrication of habitats, radiation shielding, spare parts and self-replicating machines to support future human and robotic missions.

MEI has developed a process combining microchannel reactor technology for production of ethylene with conventional reactor systems for the in-situ production of polyethylene. Polyethylene may be used alone or with regolith or recycled plastics to form composites; its potential applications are vast.

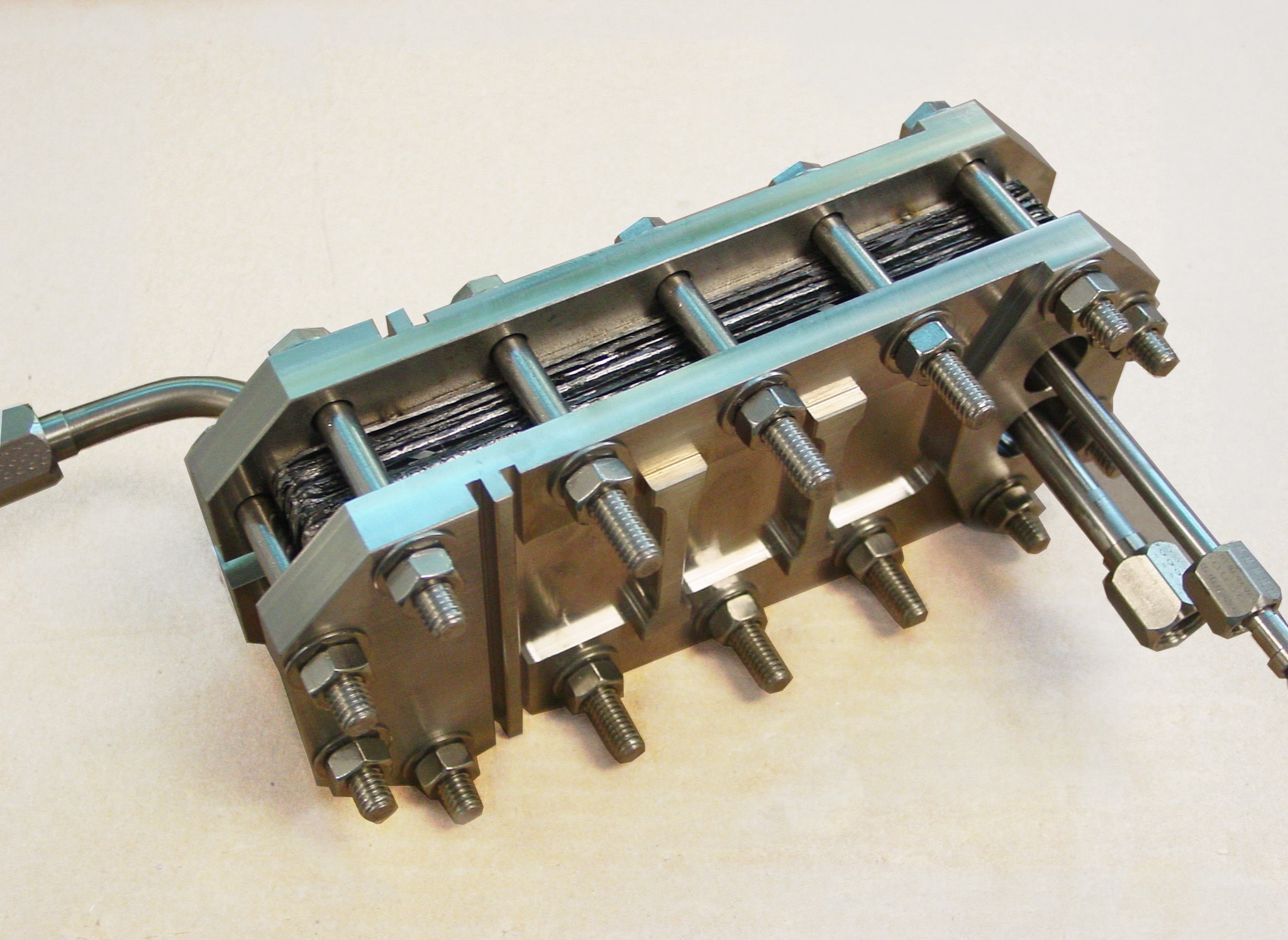

Nanocatalysts for Microchannel Reactors

Efficient chemical processing systems will minimize dependence on Earth for resupply. MEI has developed microchannel reactors using carbon nanotubes exoskeletal structures as catalyst support within microchannel layers. One of the greatest advantages of this support arrangement is the enhancement of catalytic activity by providing superior catalyst exposure to the reaction media, while maintaining catalyst integrity, enabling compact and lightweight chemical processing systems.

What We Do

© 2025 Makel Engineering, Inc. All Rights Reserved. Site by DK Web Design.